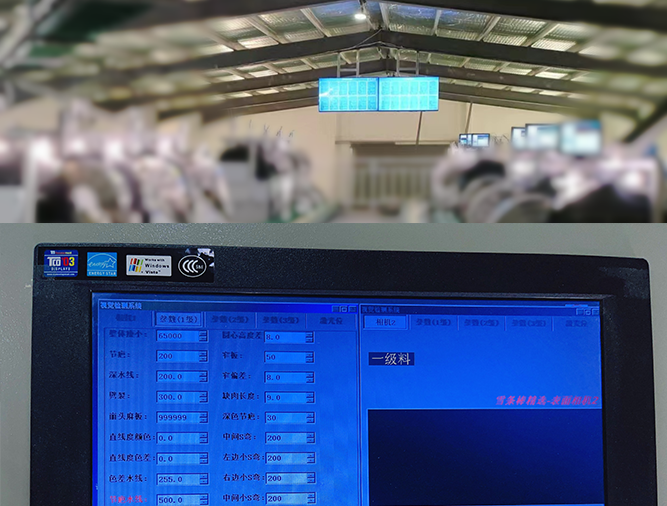

We are the only company in the industry that has achieved automated front-end and back-end production connectivity. We use advanced automation technology, especially self-developed backend selection equipment, combined with intelligent equipment and Kingdee system, to achieve full automation from log processing to finished product manufacturing. This significantly reduces manual intervention, improves production efficiency, and ensures product consistency and quality stability.

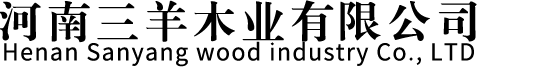

Intelligent Production

Digital operations are a key component of our smart production. All equipment is connected to the Kingdee management system, and through real-time monitoring and data analysis, we grasp production quantities, quality management, procurement data, inventory data, and sales data for order tracking. This allows us to adjust production plans timely, reduce energy consumption, and ensure environmental and sanitary standards of products.

To provide more convenient and efficient services, we have developed our own automatic counting and packaging equipment. This equipment, using advanced laser sensor technology, can quickly and accurately count products and complete packaging in a short time. Our laser sensors can detect products of various sizes and shapes, ensuring precise counts in each package.